Top Challenges in Ultrasonic Inspection

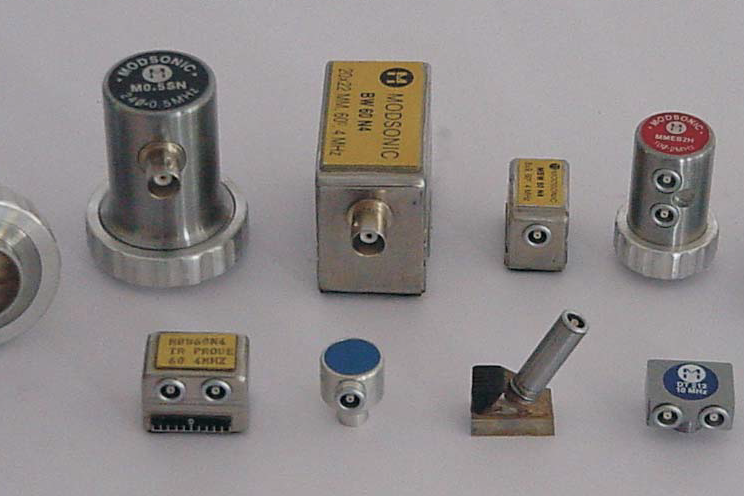

Challenges in Ultrasonic Inspection: Introduction: Ultrasonic inspection is a non-destructive testing method used to evaluate the quality of materials and detect faults and anomalies within a product. It is widely used in a range of industries such as aerospace, automotive, and manufacturing, to name a few. Despite its many advantages, ultrasonic inspection also faces…